Technology Innovation Leaders Class

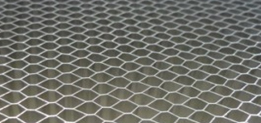

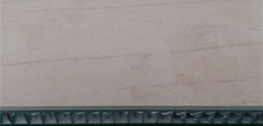

Panel and core(core material)

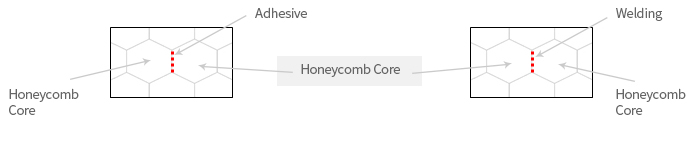

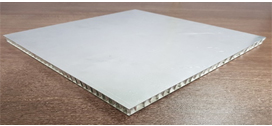

Bonded-type aluminum honeycomb panel

Excellent structural safety.

Advantageous to reducing construction period and cost through enlarged panel size .

Great in shielding electromagnetic wave which is injurious to health.

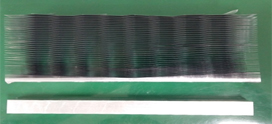

- Bonded-type aluminum honeycomb core

-

-

Block

-

When unfolded

-

- Bonded-type aluminum honeycomb panel

-

-

Bonded-type aluminum honeycomb panel

-

Aluminum honeycomb panel (marble)

-

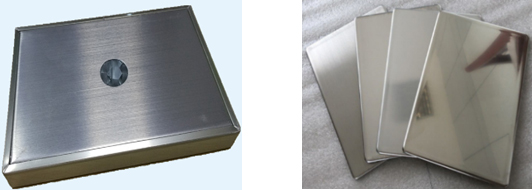

- ST’L Comb panel

-

- STS Comb panel

-

Welded type aluminum honeycomb panel

Welded aluminum honeycomb panel will be in charge of the future interior industry.

- Types of welded aluminum honeycomb panel

-

-

Single-layered type

-

multi-layered type

-

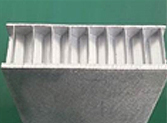

Corrugation Panel

-

punching type

-

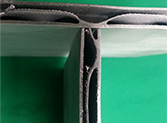

- Structure of the welded aluminum honeycomb panel

-

-

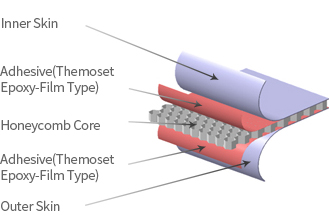

Structure of the bonded honeycomb panel

-

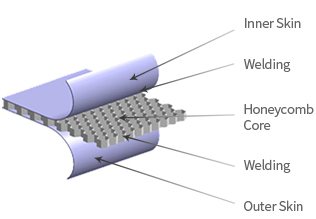

Structure of the welde honeycomb panel

-

-

Core of the bonded honeycomb panel

Core of the welde honeycomb panel

-

- Features and benefits

-

300N.mm/mm of peel strength reinforced by over 3.5 times compare to the existing products

600℃ of heat resistance temperature, over 3 times higher than the existing products

High elasticity product with no deformation or destruction at 71.4ton

Easy secondary work(welding, bending, curing) and free to select thickness between 3.5mm ~400mm

Welded type honeycomb panel allows making products which were unavailable with the bonded type honeycomb panel

- Main performance of the welded aluminum honeycomb panel

-

-

Excellent heat resistance

temperature(600℃) -

Peel strength

(300N.mm/mm) -

Tensile strength(20MPa)

-

High elasticity(71.4ton)

-

Durability and

impact resistance -

Superior buckling

performace

-

Performance test results of the welded aluminum honeycomb panel

| Number | Test List | Test Specification | Product Specifications | Test result |

|---|---|---|---|---|

| 1 | Tensile strength test | GB/T 1452-2005 (ASTM C297) |

- Upper plate thickness 2mm, - lower plate thickness 1mm, - honeycomb thickness 15mm, - whole specimen thickness 18mm |

20 MPa |

| 2 | compressive strength test | GB/T 1453-2005 (ASTM C365) |

5.51 MPa | |

| 3 | flexural strength test | GB/T 1456-2005 (ASTM C393) |

146 MPa | |

| 4 | peel strength test | GB/T 1457-2005 (ASTM C1761) |

300 N.mm/mm | |

| 5 | ball drop test | A 324g steel ball with 42.8 diameter falls from 0.8m height and the hole due to the impact is ≤10mm with no crack found around the hole | 9.2mm | |

| 6 | Static load test | Concentrated load of 2KN is applied on an area of 300mm² and neither dents nor permanent deformation is found | no permanent deformation | |

| 7 | Fatigue strength test | 1800N/10Hz/200 cycles, alternative load/span 600mm |

- Upper plate thickness 1.5mm, - lower plate thickness 0.8mm, - honeycomb thickness 19.7mm, - whole specimen thickness 22mm |

No defect |

| 8 | Noise test | GB/T 19889.3-2005. | 26 dBA | |

| 9 | Fire resistance test | EN1363-1:2012 Shall have no damage after the 45-minute test |

- Upper plate thickness 1.5mm, - lower plate thickness 1.5mm, - honeycomb thickness 17mm, - whole specimen thickness 20mm |

clear |

| 10 | Collision test | A 500g concrete ball impacts the specimen at a speed of 350km/h from 90°vertical direction and there is no penetration |

- Upper plate thickness 1.5mm, - lower plate thickness 1.2mm, - honeycomb thickness 15.3mm, - whole specimen thickness 18mm |

Crack is found on the impacted area but no penetration is shown |

- Secondary processed products

-

-

Welding with skin at 90 °

-

Welding with skin at 180 °

-

Bending Products

-

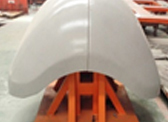

High-speed curved

products -

Right angle bending

welding products -

Pipe forming

products

-

- Application

-

Inside and outside of railway vehicles and BOX

-

Interior Panel

-

End Panel

-

Floor Board

-

Coving Panel

-

Frontal nose

-

Under Cover

-

Electrical Equipment Box

-

Skirt

Building interior and exterior materials

-

Building Exterior(1)

-

Building Exterior(2)

-

Building Exterior(3)

-

Building Exterior(4)

-

Art Wall

-

Office and classroom

-

restroom

-

Clean-room Walls

Ship and other industries

-

Aircraft exterior material

-

Aircraft interior

-

Aircraft interior

-

Soundproofing / Sound

absorbing material -

Ship Exterior Material

-

Ship interior material

-

Automobile exterior

material -

Automobile interior

material

-

Aluminum foam panel

Product made from technical innovation is not comparable with the existing products.

TILC will provide high-value technology and product.

- Structure of aluminum foam

-

- Features and benefits of aluminum foam panel

-

Excellent sound absorption performance(possible to adjust the sound absorption ration from low to high frequency by adjusting the rear air gap)

Superior durability, impact resistance, corrosion resistance and environment-friendliness

Non-combustible metal absorbing material, strong against fire

High constructability with low volume of sub-material construction, low material and construction costs

Possible to use as an aesthetic panel when painted

Specification of the aluminum foam product

| Classification | Size(mm) | Structure and construction method |

|---|---|---|

| Wall | 1,200x600x9t | aluminum foam + stud(air space) + concrete |

| Ceiling | 1,200x600x9t 600x600x9t |

M-Bar, T-Bar, Clip-Bar |

- Application of the aluminum foam

-

Buildings

Non-combustible noise absorption material for concert hall, meeting room, hall and sports and gym facilities

Non-combustible noise absorption material for general building and multi-purpose building

Non-combustible noise absorption material for renovated building

Finishing material for interior display

Civil engineering facilities / Plants / Other industrial areas

Non-combustible noise absorption material for the walls & ceilings of machine and mechanical rooms in plants

Material for walls & ceilings of operation room

For facilities for reducing the tunnel noise

The aluminum foam sound absorption material is non-combustible(no toxic gas created) and does not generate fine dust which is the essential requirement for applying as the sound absorption material inside the tunnel

Sound absorption material is 100% suitable for conditions such as water wash and it is durable against wind pressure & vibration and is appropriate for installation within the conduction gauge

Special panel and insulator

- Cubic printing panel

-

- Aluminum honeycomb type insulator

-